High-Performance Superconducting Magnet Systems

Why High-Temperature Superconductors (HTS) and Cryogen-Free Designs

High-temperature superconductors (HTS) have reshaped the potential of electromagnets by operating at elevated temperatures (20–60 K) rather than the ~4 K demanded by low-temperature superconductors (LTS). This jump in operating temperature often eliminates or drastically reduces the need for liquid helium or complex cryogenics. It also allows higher field strengths and improved thermal stability, which can be critical for advanced research, industrial processes, or emerging energy applications like fusion.

While Bi-2223 served as the backbone for first-generation HTS tapes, modern magnet developers are increasingly adopting ReBCO (rare-earth barium copper oxide) for its superior in-field current density, mechanical strength, and capacity to reach higher fields in more compact coil geometries. Multiple manufacturers worldwide have scaled or are scaling ReBCO production to meet surging demand, making it a viable—often more cost-efficient—option. By leveraging these improved HTS materials, our cryogen-free systems can offer reliable, high-performance solutions with fewer helium-related constraints. A closed-cycle cryocooler maintains superconducting temperatures, and the robust construction strategies simplify installation at remote or industrial sites, mitigate helium market instabilities, and lower overall lifecycle costs.

We invite you to learn more about HTS magnet system applications—from advanced fusion experiments to high-throughput materials testing—on our Applications page.

How Our Integrated Magnet Systems Work

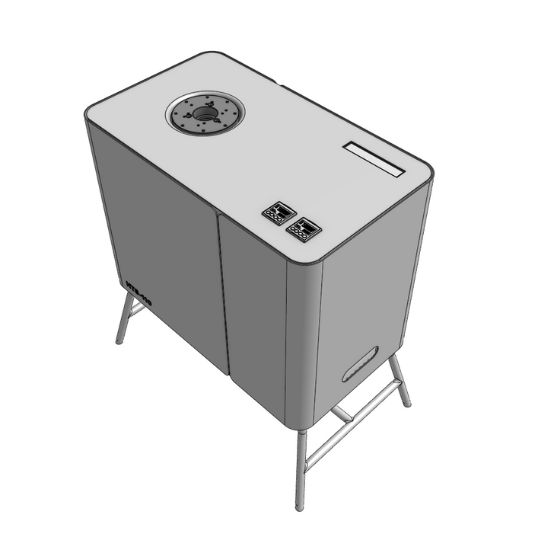

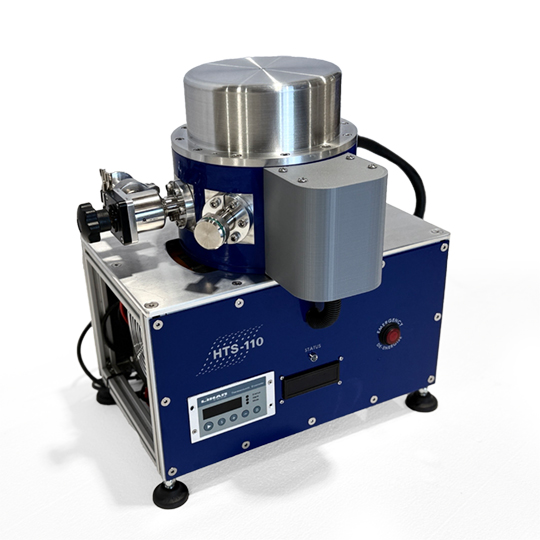

At the heart of any superconducting magnet system is a carefully engineered combination of coils, current leads, cooling hardware, and control electronics. HTS-110 designs each component to function seamlessly under the real-world conditions of your application—be it a short-duration beamline experiment, a 24/7 industrial environment, or a next-generation fusion prototype.

- Superconducting Coils.

Instead of treating the magnet windings as an afterthought, we focus on coil design from the outset, incorporating quench protection and mechanical reinforcement. Our CryoForge™ coil modules handle both standard cylindrical shapes and more unusual geometries, such as racetrack or even non-planar windings. This flexibility lets us meet the exact field profile, optical access, or thermal constraints of your lab or factory. - Current Leads and Cryocoolers.

Transferring current into the cryogenic region is where conventional leads often waste energy. CryoSaver™ leads, adapted from high-temperature superconducting tapes, drastically cut conduction losses by providing a low thermal-conductivity connection between a 60-70 K stage and the low-temperature. They pair naturally with a two-stage cryocooler subsystem, eliminating the complexity of liquid cryogens. This synergy means you can maintain the magnet at operating temperature while drastically minimising operational overhead. - Control & Monitoring.

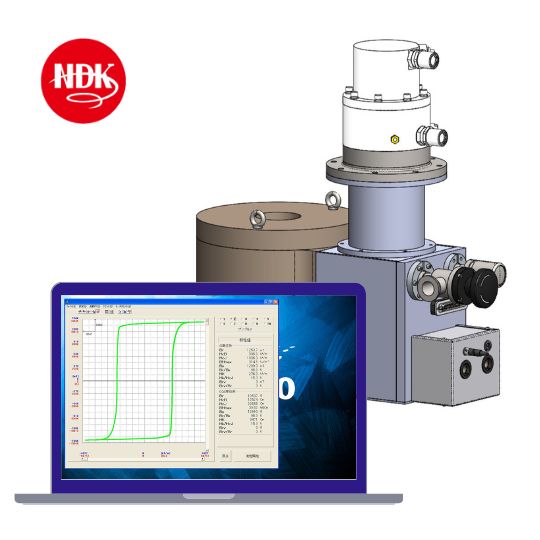

All magnet systems include instrumentation for stability protection, from thermal sensors to voltage taps that detect early quench signatures. With HTS magnets, quench propagation can be slow; careful monitoring ensures any emerging resistive zone is rapidly detected, playing to HTS’s inherent advantage of high thermal stability. Automated ramping sequences, remote oversight, and easy integration into larger workflows are standard across our offerings.

By combining each piece—coils, leads, compressor-cooling, and control logic—we create cohesive HTS magnet systems that deliver strong, stable fields, customised to your experiments or production lines.

R&D Heritage and Custom Solutions

A large part of HTS-110’s ability to meet real-world demands for high-performance superconducting systems stems from our in-house R&D lineage. Originally formed to commercialise Bi-2223–based magnets, we cut our teeth on rugged industrial needs: mine sweeper coils, energy storage prototypes, and fast-ramping test magnets for beamlines. Along the way, we tackled everything from electromagnetic modeling to mechanical support structures and quench electronics, building a deep well of HTS know-how in the process. Our track record includes:

- 5.4 T Neutron Scattering Magnets: Early integrated cryogen-free solutions that shaped our approach to moderate-field stability.

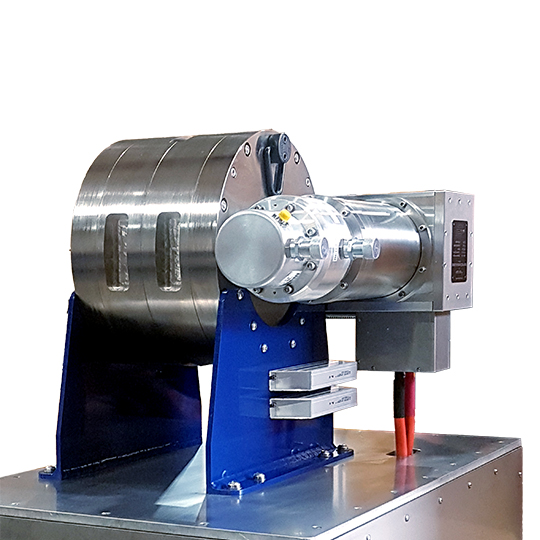

- 7 T Fast-Ramping “MOKE” Coil: Showcased the ability to cycle a magnet’s field in under 60 seconds on a continuous basis, highlighting HTS’s capacity for rapid field changes.

- 9.4 T Dry NMR Systems: Demonstrated stable, high-resolution NMR without helium top-offs.

These “world firsts” deepen our capacity to deliver custom HTS systems that accommodate unique field requirements, current loads, or rapid ramp cycles. If you require a specialised coil shape for a novel experiment, or if you’re scaling up for pilot production in advanced energy research, our engineers can adapt the entire system—magnet winding, cryocooler arrangement, quench detection, and integration—for your exact scenario.

From Concept to Commissioning: HTS-110 Helps You Move Faster

One-Stop Magnet Partner. Developing a superconducting magnet system often means juggling multiple suppliers for coils, leads, cryocoolers, and electronics. At HTS-110, we centralise every stage under one roof: from conceptual electromagnetic modeling to manufacturing and final testing. This reduces project risk and shortens the timeline, letting you focus on what matters—whether that’s neutron scattering, advanced NMR, or future-proof fusion concepts.

ReBCO Performance at Elevated Fields. While Bi-2223 formed the basis of first-generation HTS magnets, ReBCO (rare-earth barium copper oxide) tapes open the door to higher fields, smaller coil footprints, and greater mechanical strength. For labs and industries pushing beyond Bi-2223’s limitations, ReBCO enables more compact designs and improved in-field current density — all at the elevated temperatures (20–60 K) where HTS magnets thrive. Its robust engineering margins also help accommodate rapid ramp cycles or high mechanical loads, making ReBCO an ideal choice for advanced fusion prototypes, high-throughput industrial lines, and beyond.

Helium-Free Operation. By operating at 20–60 K, most of our magnets either minimise or eliminate helium usage, circumventing the supply chain headaches and costs tied to helium. Instead, a carefully dimensioned closed-cycle cryocooler maintains the superconducting temperature, maximising uptime while reducing logistical hurdles—ideal for remote or continuously operating facilities.

Tailored Scalability. If you’re prototyping a new process or building a pilot plant, we can design a baseline system that grows with your needs. Expand coil modules, ramp up current leads, or add advanced control electronics as your research evolves. Our design studies ensure each element is prepared for future expansions without re-inventing the entire magnet architecture.

Ready to Transform Your Project with HTS?

HTS-110 stands ready to deliver high-performance, cryogen-free magnet systems that bring the real advantages of 1st and 2nd generation HTS tapes, integrated quench protection, and minimal helium dependence. Whether you’re in advanced materials research, industrial quality assurance, or scaling up for fusion, our proven R&D and manufacturing expertise can streamline your journey.

Reach out today to learn how we can customise a superconducting solution—be it a compact system for a specialised experiment or a pilot-scale magnet for a next-generation energy concept? Contact us today.

We look forward to helping you unlock high fields, stable operation, and a simpler cryogenic environment with HTS.