Custom design and manufacture acts as an incubator for next-generation products such as in green energy and transportation developments. For projects with substantial technical risk HTS-110 undertakes development with a systematic approach. A design study is often undertaken to identify project feasibility and to scope possible solutions in conjunction with associated costings. From design to commissioning, we ensure that client intellectual property is respected at all times.

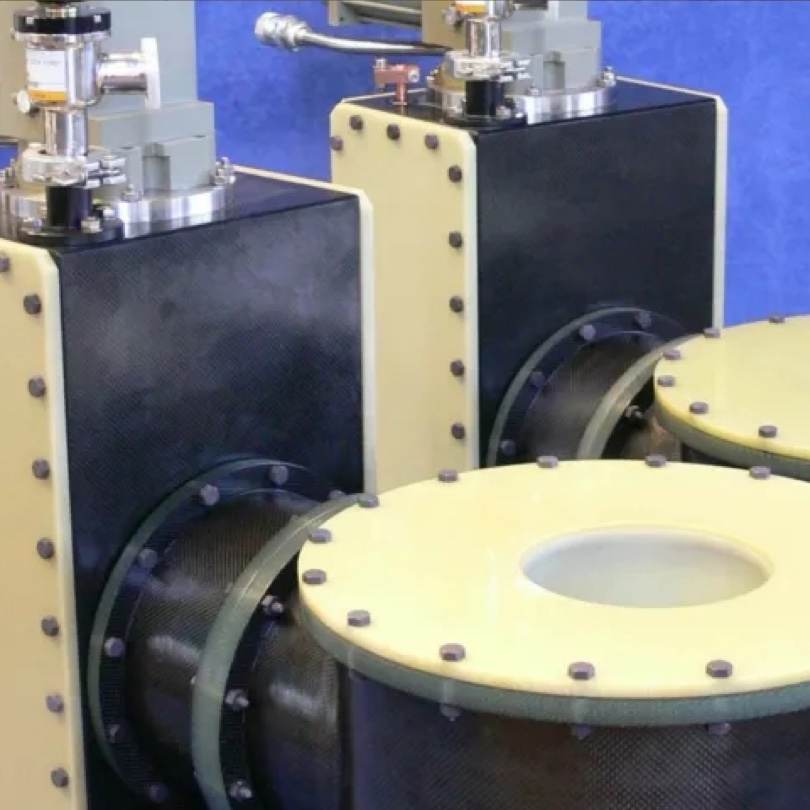

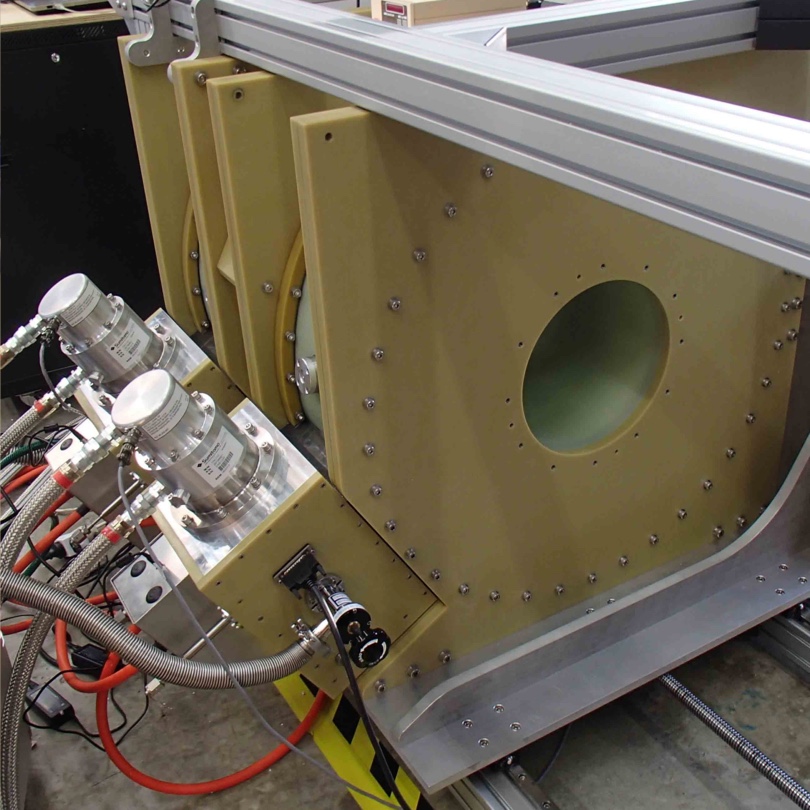

Specific field profiles or uniformity targets, low fringe field, wide optical access to the central field region, dimensional and weight constraints, compatibility with physical rotation, minimisation of eddy currents, AC and fast-ramp operation: these are all constraints that HTS-110 has addressed in custom magnet designs.

Systematic approach

Design flexibility

HTS-110 employs leading software tools in the design of custom solutions. With our trusted supplier network we offer wide flexibility in construction materials to meet demanding specification targets; high-performance composites, low-carbon steels, through to high-strength alloys: all feature in our custom magnet systems.

Any project size

From individual coils and bespoke HTS current leads through to complete magnet systems, HTS-110 is able to deliver across a broad range of custom projects. Coil sizes to over 1.6 m have been manufactured, with robotic winding in development able to deliver a much broader range of sizes and coil types. Magnet systems from simple pancake coil assemblies though to complete dipoles of over 3 tonnes feature in our catalogue of successful projects.

Get in touch

Questions? Interested in a product? The HTS-110 team is here to help.

Enter your details below or see more contact methods.