Our cryogen-free HTS magnet solutions are engineered to provide:

Higher Field Strength: HTS enables stronger magnetic fields than LTS, essential for next-generation tokamak and stellarator confinement, leading to smaller, more efficient, faster to develop fusion reactors.

Truly Cryogen-Free Operation: Simplifies complex engineering and cryogenic infrastructure by eliminating liquid helium dependence, mitigating “Helium Shortage 4.0” risks and costs. This allows for rapid cooling and setup.

Enhanced Stability & Quench Management: HTS offers higher thermal stability margins. HTS-110 integrates robust monitoring (temperature, voltage) and protection systems, leveraging extensive experience to ensure reliable operation crucial for long-duration plasma experiments.

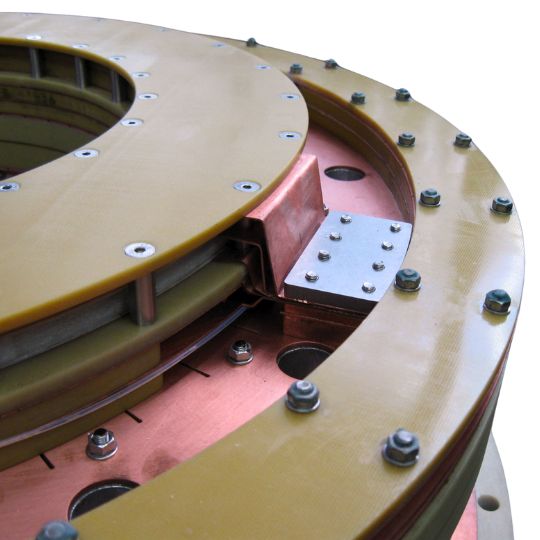

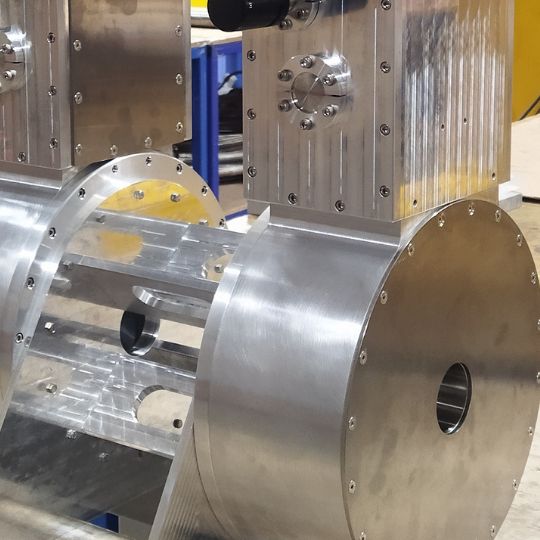

Compactness & Design Flexibility: Higher current density in HTS conductors allows for more compact magnets and the complex, non-planar winding geometries often required for stellarators. We offer options for room temperature or cold bore, adaptable for various temperature control needs.

Advanced Shielding & Field Control: Sophisticated passive and active shielding options ensure precise field control and minimal fringe effects.

Versatile Supports & Orientation: Our magnet systems can be designed for any field orientation to suit diverse experimental setups.

Faster Ramping: The enhanced thermal stability of HTS materials allows for fast magnetic field change, beneficial for certain control schemes or experimental protocols.