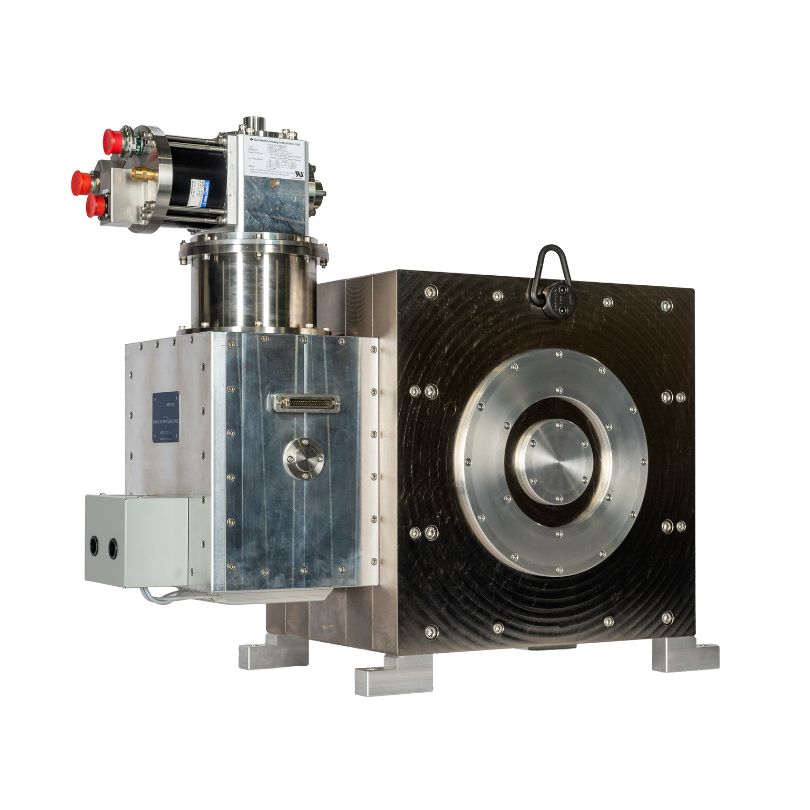

At HTS-110, custom HTS magnet design isn’t just an add-on—it’s how we started. For nearly two decades, our dual-role R&D team has tackled everything from fusion coils with unique geometries to industrial test rigs needing fast ramp rates or extreme thermal stability. Every custom project builds on the engineering depth behind our proven CryoForge™ coils, CryoSaver™ leads, and fully cryogen-free product lines, ensuring you benefit from both in-house innovation and field-tested reliability.

Discuss your goals; we’ll finalize the geometry, conductor choice, and ramp profiles—delivering a magnet that powers new breakthroughs. We transform your specialized performance requirements into a robust HTS solution—one that stands up to real-world demands, from pilot-scale experiments to 24/7 industrial operations.

Working Side-by-Side with Your Team

Our process begins with feasibility and design studies—covering electromagnetic modeling, conductor selection (Bi-2223, ReBCO, other), thermal loads, and quench safety. From there, we develop a tailored manufacturing plan, integrating coils, leads, cooling, and monitoring into a seamless package. That means one partner for concept, winding, assembly, and testing—saving you time, cost, and the hassle of multi-vendor integration.

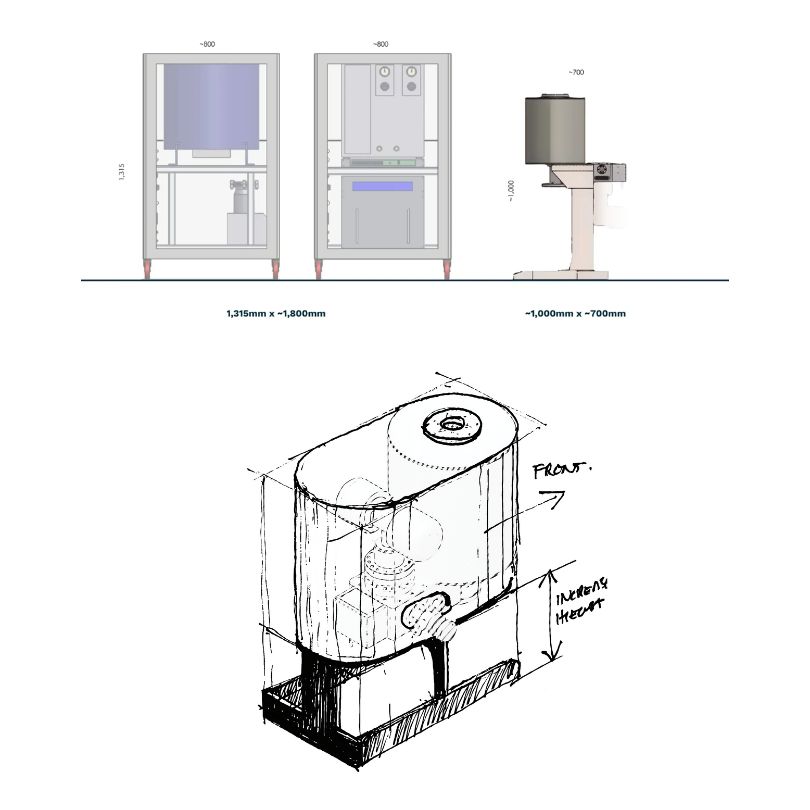

Whether you need a 2 T compact magnet for a specialized NMR experiment or a 15 T coil segment for a pilot fusion device, we adapt our modular architectures to your field needs and mechanical constraints. The result is a custom solution you can trust, underpinned by decades of HTS machine design. We address:

- Operating Temperature (20–77 K)

- Field Strength & Uniformity

- Fast-Ramping or Static Operation

- Optical/Mechanical Access

- Quench Detection & Safe Shutdown

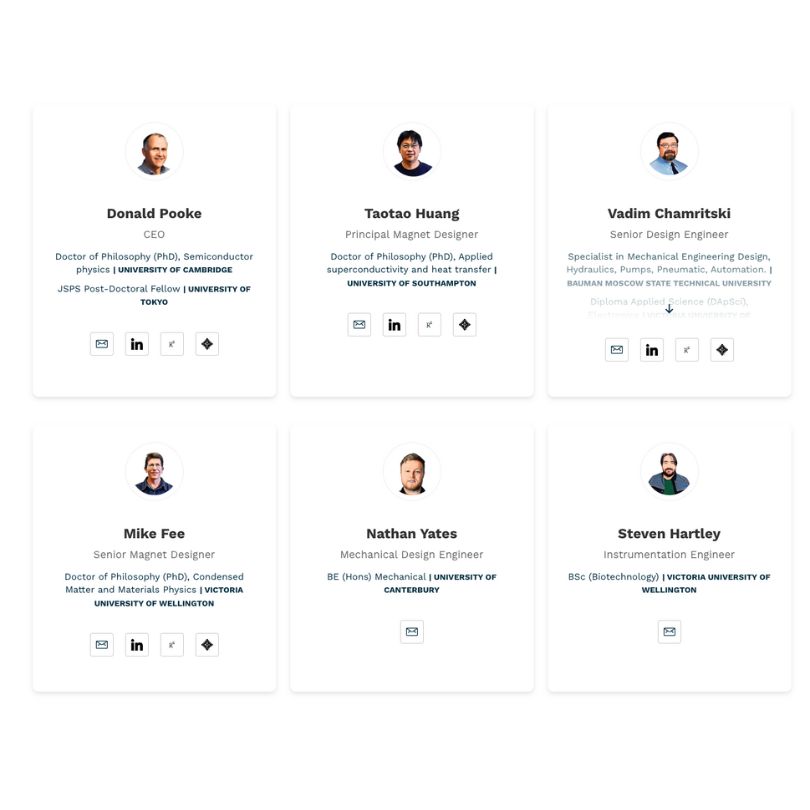

Our Engineering & Design Team

Behind each bespoke system is a multi-disciplinary group of engineers and scientists who live and breathe HTS technology. With backgrounds in electromagnetic modeling, mechanical engineering, cryogenic design, and quench propagation analysis, our team has repeatedly delivered “world first” magnets across varied fields—from advanced beamline instrumentation to fusion R&D.

By unifying these skill sets under one R&D lab, we provide a swift, iterative path to final design, rather than a lengthy handoff between disjointed groups.

From Concept to Commissioning: Typical Project Flow

Initial Discussion | We gather key specs—target field, geometry, ramp profiles, conduction losses, temperature range—to frame the project’s scope and performance goals.

Feasibility Modeling | Next, we run preliminary electromagnetic (EM) calculations, quench risk analysis, and mechanical stabilisation assessments to ensure safe coil operation. We also recommend a suitable conductor (Bi-2223 or ReBCO) based on in-field critical current and thermal margins.

Detailed Design | Once feasibility is established, we finalize the coil layout, design the cryostat, integrate quench electronics, and specify mechanical reinforcements for high-field stability.

Manufacturing | We handle coil winding, lead fabrication, and subsystem testing in a controlled cryogenic environment, verifying that each element meets its operational specifications.

Validation & Delivery | Following assembly, we conduct full-system acceptance tests, then ship and optionally assist with on-site installation. Throughout these steps, we maintain open communication, refining details as needed if requirements evolve.

Collaborate with Our R&D Lab

Whether it’s a fast-ramping magnet for complex beamline studies or a high-field coil to push next-gen fusion research, our R&D Lab offers a rare blend of dual-role innovation (practical engineering and advanced R&D). Let’s discuss your unique application and uncover the right combination of coil geometry, cryocooler strategy, and quench safeguards.

Contact us today to initiate a feasibility review or simply explore the possibilities of HTS magnet technology tailored to your vision.

With HTS-110, you gain a partner focused on real-world outcomes—bridging the gap between advanced theory and reliable, high-performance superconducting systems.

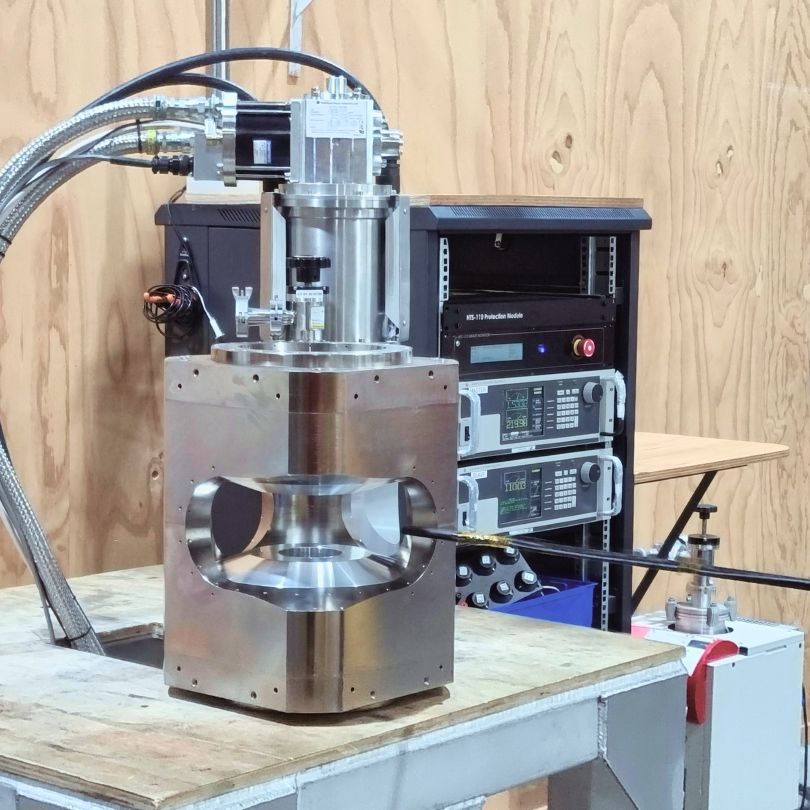

Field Update: Custom High-Tc Magnet in Agricultural Research

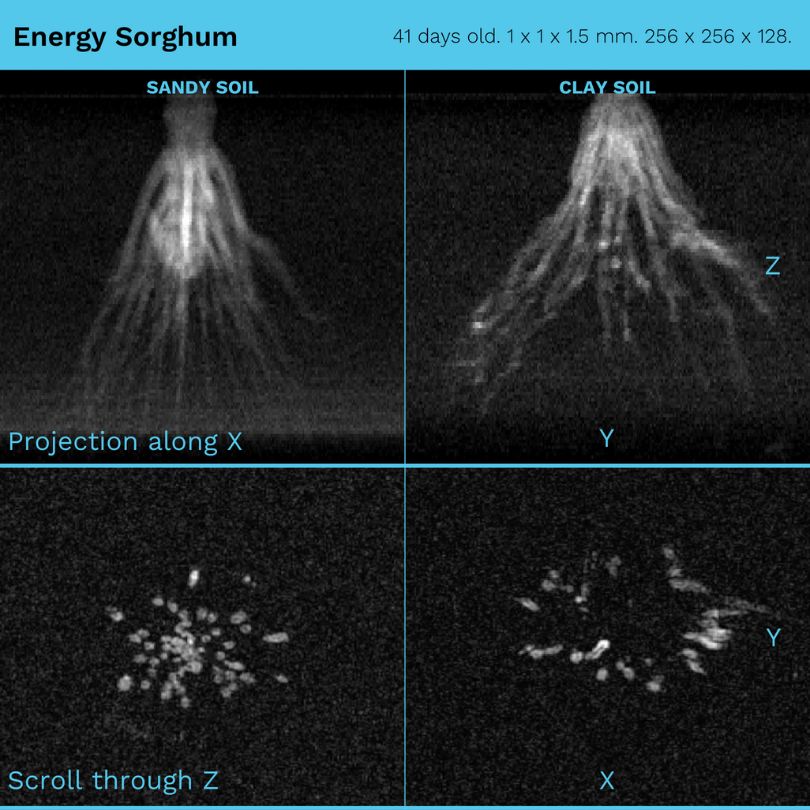

HTS-110 recently collaborated with ABQMR, Texas A&M Agrilife, and Harvard University, to develop a unique high-Tc superconducting magnet system for imaging applications in agriculture. This custom solution was designed to address the specific challenges of scanning plant roots through natural soils, which are often magnetic, using a magnetic field of 0.15 T. The system was integrated into the Texas A&M greenhouse research and over the past three years provided advanced imaging capabilities for detailed studies of intact root structures.

Texas A&M initially faced issues with their copper magnet (0.05 T), which provided insufficient field strength for their application. ABQMR approached us to explore a high temperature superconducting magnet cooled with liquid nitrogen to achieve higher field strengths, alongside other primary considerations of low cost and ease of use in the field. Working within the tight constraints HTS-110 delivered a tailored solution ready for work.

Paraphrased Customer Feedback:

It was great to meet you at ENC. The magnet you built for us was integrated into an imaging system and sent to Texas A&M in December 2020. It was designed for use in the agricultural field and ultimately found its home in the greenhouse seeing heavy use for around three years, scanning many different plant root samples.

Hilary Fabich, PhD. ABQMR President

Budget-Conscious Design: The cryostat was designed with cost constraints in mind, prioritizing affordability over absolute efficiency. The concept involved using a sub-cooled liquid nitrogen bath, vacuum-pumped to about 150 Torr, to provide additional performance.

Operational Time: The system operated effectively for 6-7 hours after cooling to about 66 K, balancing performance with practical handling considerations.

Visualization Capabilities: Custom High-Tc Magnet in Agricultural Research

Provided 3D imaging of plant roots in soil.

By partnering with HTS-110, you gain access to our extensive technical expertise and innovative solutions, enabling the rapid development of reliable and high-performance custom magnet systems. Contact us to discuss your specific requirements and discover how our expertise can benefit your applications.